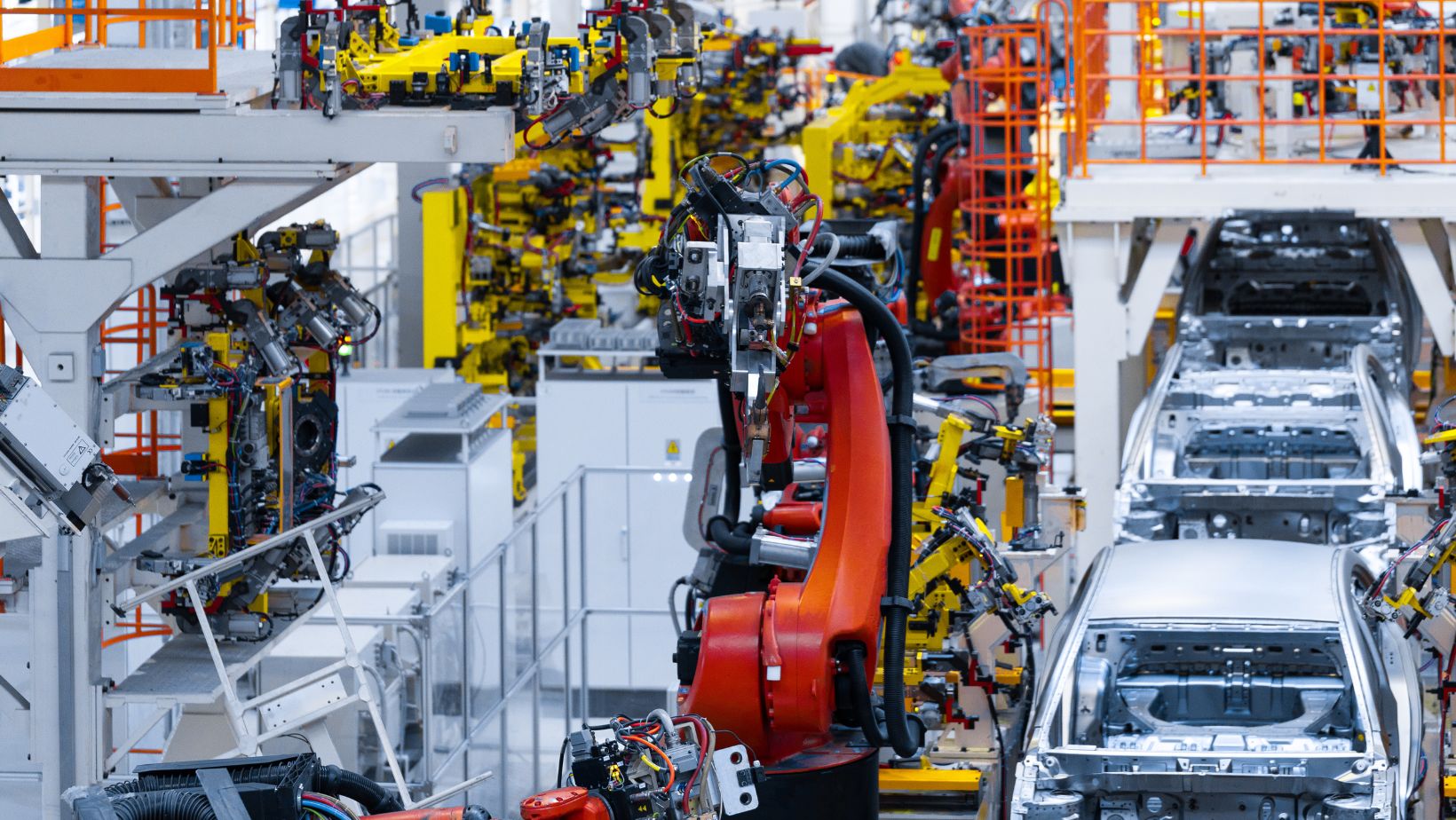

In the ever-evolving world of automotive manufacturing, flexibility is key. With the increasing demand for unique and complex designs, manufacturers are constantly seeking innovative ways to stay ahead of the curve.

From the use of advanced materials to cutting-edge manufacturing techniques, the industry is transforming at a rapid pace.

Embracing Advanced Materials

One of the significant advancements in automotive manufacturing is the use of advanced materials. These materials not only enhance the aesthetic appeal of vehicles but also contribute to their performance and efficiency. Plastics, in particular, have become a vital component in creating complex shapes and designs.

The Role of Plastics in Automotive Design

Plastics are incredibly versatile and can be moulded into intricate shapes that traditional materials like metal cannot achieve.

Companies like Simply Plastics provide a wide range of plastic materials that allow for more innovative and aerodynamic designs. From lightweight panels to durable interior components, plastics are at the forefront of modern automotive design.

Innovative Manufacturing Techniques

Advanced manufacturing techniques have revolutionized the automotive industry, enabling the creation of complex shapes and designs with unprecedented precision.

3D printing, for instance, allows for the production of highly detailed parts and rapid prototyping, significantly speeding up the development process.

Injection moulding, on the other hand, is ideal for high-volume production, producing parts with intricate details and consistent quality by injecting molten plastic into moulds.

CNC machining, or Computer Numerical Control machining, involves using computer-controlled machines to remove material from solid blocks, creating precise and high-quality parts.

These techniques collectively enhance the flexibility, efficiency, and cost-effectiveness of automotive manufacturing, paving the way for innovative and customized vehicle designs.

Benefits of Flexible Manufacturing

Flexibility in automotive manufacturing offers numerous benefits, including improved aesthetics, enhanced performance, cost efficiency, and customization.

The ability to create complex shapes and designs allows manufacturers to produce visually appealing vehicles that enhance brand image and attract more customers.

Innovative designs contribute to better aerodynamics, reduced weight, and improved fuel efficiency, with advanced materials like plastics enabling lighter yet durable vehicles.

Flexible manufacturing techniques also reduce production costs by minimizing waste and enabling rapid prototyping, leading to shorter development cycles and faster time-to-market for new models.

Additionally, this flexibility facilitates customization to meet specific customer requirements, including personalized interior designs, unique exterior shapes, and specialized features.

Closing Statement

The journey towards more flexible automotive manufacturing is well underway, and the possibilities are endless. By embracing advanced materials and innovative techniques, you can be part of this exciting transformation, creating vehicles that stand out in both form and function.

Remember, the key to success in automotive manufacturing lies in the ability to adapt and innovate. Whether you’re a designer, engineer, or enthusiast, staying informed about the latest trends and technologies is crucial. So, keep exploring, experimenting, and pushing the boundaries of what’s possible in automotive design.

In this ever-changing industry, the potential for innovation is vast. Embrace the flexibility that advanced materials and manufacturing techniques offer, and you’ll be well-equipped to create the next generation of remarkable vehicles.